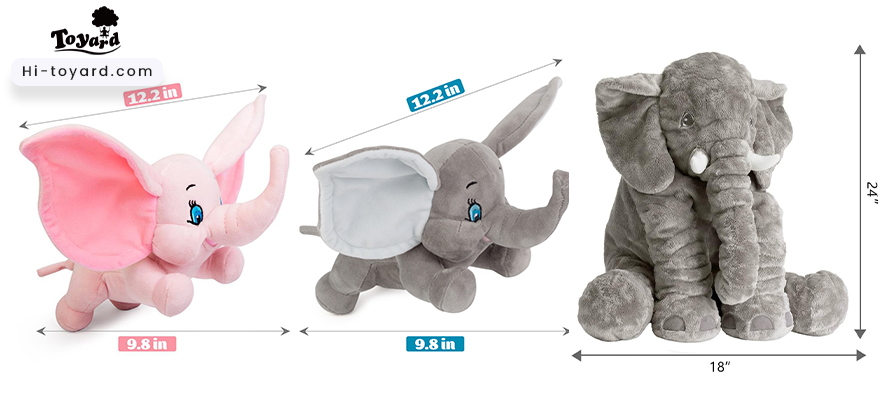

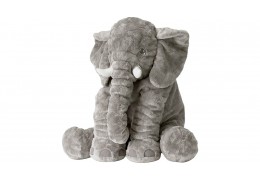

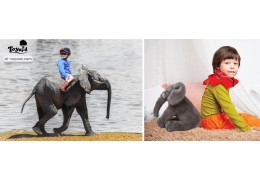

The presence of such massive elephants implies that they are simple to play with. Adults, like children, require...

How can We Help the Customer to Make a Custom Animal Plush Toy?

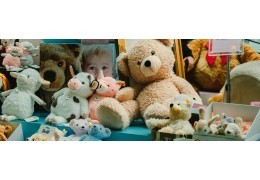

Our hot item is the plush elephant toy nowadays. That is due to the fact that these elephants face a serious crisis that needs to be solved. We have to divert our attention towards elephants to save them, and Toyard's objective is exactly the same. We want to do it through a plush elephant toy.

We, as a toy manufacturer, want to draw attention towards the Asian elephants, and this is the best we can do. We launch cute plushies in the form of giant stuffed animals that are used in homes, offices, and other places as a gift, souvenir, or just as a casual toy.

However, our company, Toyard, is not only a plush elephant manufacturer. We can manufacture any type of custom stuffed animals. We manufacture custom plushies depending on the need of the customer. If the customer needs custom plush dolls, we can make those too. We are proper manufacturers of custom plushies. We can also engrave the logo of your desired company on the custom plushies. We have a whole process of manufacturing the custom stuffed animals.

what can manufacture wonderful looking custom plushies

· Sample making is done initially. There are different types of samples. A sample may be an idea in your mind. You can discuss that idea with us, and we can give your idea a practical shape. A thought, a concept, or a whole idea about a stuffed animal plush toy is enough for our qualified team to initiate the process and prepare a sample. Our experts will then decide the physical characteristics of the practical model. The physical characteristics will be according to the sample. All measurements will be done accurately.

· The die-cut press machine then cuts the parts into desired sizes. It is a vital stage for the production of custom plushies. The proper cutting is very critical to the final design. If the cutting is not done properly, it can lead to defects in the final model.

· The fluffing machine is where the fun begins. The custom stuffed animals are known for their fluffy feeling. Children adore the fluffiness of the custom plushies, and love to play with them. The secret behind such a lovely, soft, and comforting feeling of the plushies comes from the fluffing machine that performs the job of filling up the plushies with a soft polyester that gives the plushies their identity of being soft and silky. The fluffing machine is the reason for the fluffy feeling of the best-stuffed animals, such as the elephant. After the addition of the polyester, the fluffy toys are stitched to perfection using machine sewing needles and hand sewing needles.

· After that, the custom plush toys go on a conveyor belt. The next purpose is to pack these lovely giant stuffed animals in heat-sealed packets. They are packed to make sure that they remain in their best state when they reach the customers. Taking these cute plushies outside the sealed box is one of the best feelings for the children.

· To make sure that there are no impurities, the packed custom-made stuffed animals are run through an X-ray-type contamination detector. It makes sure that there are no unwanted particles inside the packaging. If any impurities are detected inside any of the giant stuffed animals, they are immediately removed, and the cute plushies are packed again to make sure there are no impurities.

· The machine sewing needles control ensures that every needle that is used is accounted for. A new needle can only be availed if you return the old broken needle to the control center. This is very helpful as every single needle is accounted for due to this machine.

· The same procedure as the machine sewing needles control is applied to hand sewing needles control. Even the hand needles are all accounted for, making sure that no needles are wasted.

· Finally, the testing phase is the last phase, where different tests are performed on the specimen to make sure that it is physically capable of what we want it to be. The tests are done to make sure that there are no unwanted characteristics and the physical aspects such as the strength and durability of the custom stuffed animals are according to the expectations. These tests may test the endurance of the cute plushies and the physical traits of these giant stuffed animals before sending them to the suppliers. If the tests yield satisfactory results, the cute plushies are sent to their destined stores from where the kids pick them up.

If all the processes are done properly, and the desired results are achieved, the product is introduced in the market. However, if any of the above-mentioned processes go wrong, we make sure that we rectify all the wrongs and repeat the process to get the desired result. Because Toyard means "Perfection," and we make sure to practice perfection on the inside to achieve perfection on the outside in the form of most wanted custom plushies. The giant stuffed animals are not easy to manufacture. Toyard makes sure that each and every step is carefully monitored along with an expert team for each process. The hard work of our team becomes visible on the faces of little kids that play with our cute plushies.

Conclusion

We have discussed the steps to manufacture the cute plushies in this article. We hope that, after reading our article, you will have a clear idea about our processes to design a custom plushie. Even the slightest idea about a stuffed animal can become a reality. Our expert team makes sure that we accommodate all the wishes of our dear customers.

Reprint statement of blog content: All the blog content and image are original, copy right by hi-toyard.com. The reprint statement must be included with our permission. Toyard are not responsible for reprint for similar content or contains trademark and other infringement reprint statements. Please contact us if there is infringement content.

Posted in: Plush toy

Top authors